Boiler Heat Exchanger Cleaning

Understanding Boiler Heat Exchangers

A boiler heat exchanger can be used for many purposes; the general function of this device remains quite simple: to transfer heat from the boiler to other systems or appliances. Among the most ubiquitous uses for these devices is to transfer heat in hot water from the boiler to an indoor heating system, hot water storage system (e.g., a hot water system that powers hot water taps), or a snow melting system.

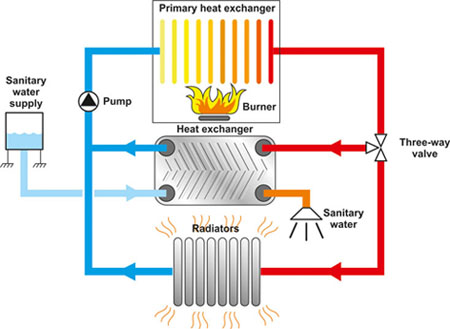

The boiler heat exchanger is the place where hot water from the boiler heats water (or any other fluid for that matter) from other systems. For example, cold sanitary water from a home’s water line will pass through the boiler heat exchanger before it goes to the hot water taps. In the heat exchanger, the hot water from the boiler transfers its heat to the cold sanitary water. The result is hot sanitary water that can be used from the water taps in the house.

The following diagram illustrates the flow of water and heat in a house. Hot water from the boiler is sent directly to the heating system of the house; but the sanitary water coming into the house must be heated without mixing with the water from the boiler. Again, the process of heating the sanitary water is accomplished by a boiler heat exchanger.

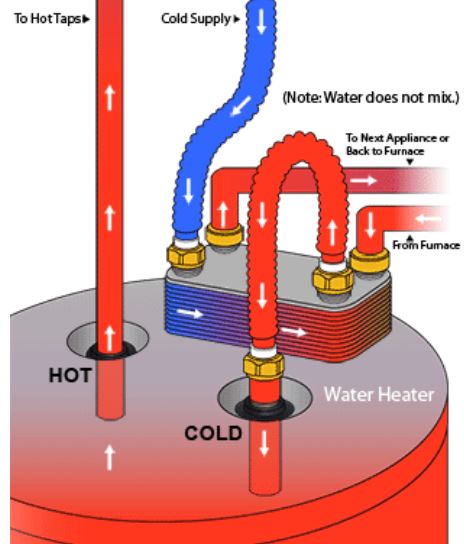

A furnace boiler can also work in congress with a hot water heater through the use of a heat exchanger. In the following diagram, hot water from a furnace is sent to a heat exchanger. Sanitary cold water is also sent into the same heat exchanger. The furnace heat exchanger allows the water heated by the furnace to impart its heat into the cold water before it is stored in a hot water heater. The hot water heater can then be used to further heat already heated water. This allows the furnace to assist in the process of heating water.

Cleaning Boiler Heat Exchangers

There are different types of heat exchangers that can be utilized with a boil. Whether its a plate heat exchanger, shell and tube, or any other kind; Flushing Services can get it clean. Because these devices can be expensive, replacing a dirty unit may require a significant cost. Even smaller units may be much cheaper to clean than replace.

You may have seen chemical solvents on the market that are made to clean heat exchangers. These solvents can be dangerous to use, and they won’t get your heat exchanger totally clean. The debris they leave behind will simply form a scaffolding that new debris and fouling can collect on. The result is, you may need to keep repeating the cleaning process with solvents every few months. This not only is costly in terms of time, but also the expense of the solvents can add up over the years. And, of course, the process is dangerous—those solvents are so strong they can easily damage the skin and eyes.

If you want your heat exchanger to be thoroughly clean, and ready for optimum performance for the foreseeable future, you need to get it professionally clean. And, you might be surprised at how cost effective this process can be.

Flushing Services cleans heat exchangers of all varieties; from small units to large industrial devices. Business from a host of industries, and the United States government, trust us to clean their heat exchangers. We have the expertise to get the job done efficiently, and completely. Our service will provide you with a device that is truly clean; this is much more than a simple flush with caustic solvents can provide.

Our Cleaning Technology

Flushing Services is a sister company of Hot Flush; both owned by the same company. The Hot Flush machine is a patented transmission and heat exchanger cleaning device. This patented technology can remove 99.9% of the debris and contamination from transmissions. This same technology can be, and is, used to clean heat exchangers.

In addition to our patented Hot Flush technology, we incorporate a variety of other proprietary cleaning techniques into our cleaning process. It is important to remember that each heat exchanger is different, and is used in different ways. Depending upon such unique factors, we develop a customized cleaning protocol for each heat exchanger.

By crafting a unique cleaning procedure for a heat exchanger, we are able to efficiently, and consistently, arrive at the final result of a total clean device. To find out more about our cleaning techniques, you can learn more at this page on our website: Flushing Services Cleaning Technologies.